Téchne lubrication fittings

To eliminate some of the problematic issues regarding lubrication fittings (grease fittings) Sealweld and Téchne has developed a new type of lubrication fitting. From the outside there are not a big difference compared to other button head fittings with cap, but looking at the internal parts there are some important differences.

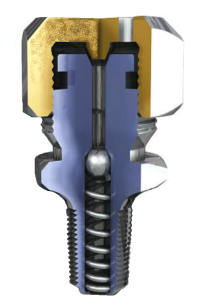

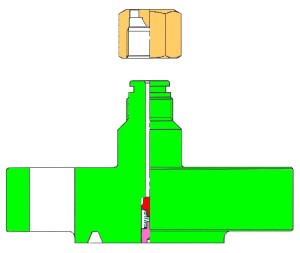

Looking at the drawing of the regular lubrication fitting bellow, one can see a fold under the spring witch holds the spring and ball in place. Any fold will be a week point witch can brake if one is pumping with too high pump pressure. When folding metal there will come into being small cracks witch make this fold a week point. If pumping with too high pressure the spring will be all squeezed together and the flow path through the fitting will be substantially reduced if not blocked, and the increasing of the pump pressure can compress the spring and the ball out of the fitting, and you do have a problem.

The ball in the fitting can also be a source of problems. When under normal operation there can be a build up of sediments around the seal area of the ball, due to vibrations there can be worn a small groove on the ball surface. The sediments and the groove will basically not be a problem, but when pumping through the fitting the ball can rotate slightly and after injecting not be settled in the same position as earlier, and now you have a leak.

The Téchne and Sealweld solutionson the problems are three adjustments.

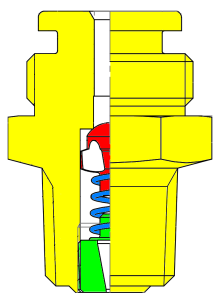

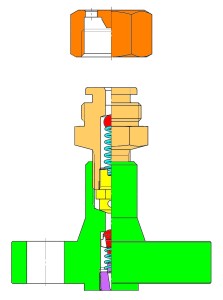

The internal part are not kept in place by a fold, but by a small bolt screwed into the bottom of housing. This bolt do have a small pivot stopping the check to over compress the spring and reducing the flow area through the fitting. As the drawing of the Téchne fitting shows the are no ball but a guided dome working as the check in the fitting. After pumping into the fitting the dome will return to the exact same position as before pumping due to the guiding of the movment. All problems eliminated.

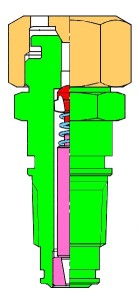

Téhne are producing lubrication fittings in all sizes an with all kind of connections like; NPT – NPTF – BSPP – UNC – UNF – Flange connection. The fittings can be with single seal – douoble seal or tripple seal as illustrated on the drawings bellow.

Téchne axillary valves

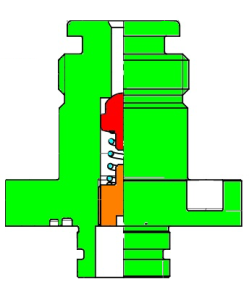

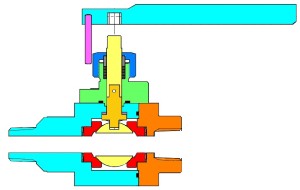

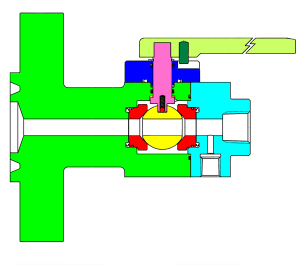

As a part of there special valve selection Téchne are producing axillary valve to be installed on the body of bigger ball and gate valves. To be able to maintain or test valves one must have a way of communication into the cavity of the valves. There may be a need of pressure reduction to test the integrity of the valve seal or to create a double block across the valve, or maybe a cleaning of the valve internal parts has to be done by pumping solvent into the cavity.

The left hand valve are a standard ball valve with male and female NPT connections. The special item with that valve is the loos handle. One of the problematic situation that can arise on small 90 degree operated valves are a undesirable opening of the valve by accident. To eliminate that possibility the handle is loos and are hung by the side of the valve after operation.

The valve at the right hand side are a test valve where there are a 1/4″ NPT test port after the ball but in front of the outlet of the valve. To test or maintain the main valve a standard axillary valve are installed in the outlet of the test valve and a gauge are fitted into the test port. By closing the outer valve and opening the inner valve the cavity pressure are monitored. One can reduce or increase the pressure in the cavity to obtain the desirable function.

Due to the risk of breakage NPT connections are not the preferred connection into a valve housing, often there are flange connections machined onto the body of the main valve. The same axillary valve are produced with flanges. Now the male NPT are replaced with a flange of any type and pressure rating. The flange can be a compact or a ANSI RTJ flange whatever are on the main valve.

Even if the flange are a 2″ RTJ on a 36″ class 1500 ball valve, the axillary valve will be a single 1/2″ ball class 1500. It is important to keep the weight and dimensions as low as possible on the axillary valve.

During the normal running of the plant it is only the inner axillary valve that will be install on the main valve. The test and outlet of the valve are to be blocked by the use of bleed plugs, and the axillary valve are to be in the closed position without the handle on the valve.

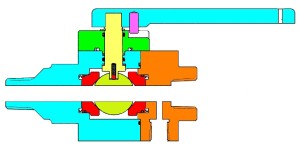

Téchne are also producing special adapted valves like the valve below. This valve is a combination of a 1/2″ ball valve with 1/4″ gauge and a needle valve at the end. In the needle valve after the seat there are a 1/2″ hole for injecting sealing componet in case of a spindle leak. This is valves installed on old valves where one is concerned fore unpleasant surprises.

For more information please take contact.