Lubricants an pump equipment from Sealweld

Sealwels, a Canadian company specialised in valve maintenance equipment. They are producing solvents – lubricants – pumps and pump equipment for valve maintenace.

Solvents

There are two main types of solvents, one in liquid and one in the form of gel.

Odyssey industrial cleaning solvent

Sealweld Odyssey Cleaning Solvent is a synthetic industrial cleaning solvent. Excellent for removing heavy deposits of grease, lubes and heavy oils, as well as removing sludge and dirt from metal parts. Sealweld Odyssey Cleaning Solvent will not harm metal, most types of rubber, plastic or concrete. It is excellent for dissolving asphaltene build-up, and has many other uses in the industrial marketplace. Sealweld Odyssey Cleaning Solvent does not contain water and is not water-soluble, on the contrary it leaves behind a protective barrier that inhibits spot rust. This non-flammable, non-hazardous, and non-polluting solvent is as safe for the person using it as it is for the environment. Use as a valve body flushing solvent for sized or hard to turn valves

Temperature: – 29°C to + 232°C

Delivered in drum: 170 liter Pail: 19 liter Bottle: 4 liter

Valve Cleaner Plus

Valve Cleaner Plus is not a sealant, it is a combination of solvent and semi-synthetic lubrication oils. Formulated to be injected directly into the seat sealant system to clean important seal faces and sealant passages. Cycle the valve (if permitted) to ensure complete coverage, to allow the valve cleaner to soften old sealants and remove residual build-up from seal points. Valves with severe or persistent leakage may require more wait time. The best results are achieved by displacing the valve cleaner with equal quantities of lubricant/ sealant after cleaning. Recommended for use in ball, gate or plug valves and orifice fittings. For use at refineries, wellheads, pump or compressor stations and in gas distribution systems.

Pressure up to 690 bar (10 000 PSI)

Temperature: – 40°C to + 204°C

Delivered in drum: 163 or 50 kg Pail: 16 or 4 kg Cartridges: 400 gram

4,5 kg pail are used directly with the pneumatisk pumpe Active-8 and the cartridges are to be used with the manual hand pump Super gun screw-primed pump. Cartridges are delivered in boxes of 12 cartridges.

Lubricants

Equa-Lube Eighty

Pressure up to 690 bar (10 000 PSI)

Temperature: – 40°C to + 149°C

Delivered in drum: 181 or 54 kg Pail: 18 or 4,5 kg Cartridges: 430 gram

4,5 kg pail are used directly with the pneumatisk pumpe Active-8 and the cartridges are to be used with the manual hand pump Super gun screw-primed pump. Cartridges are delivered in boxes of 12 cartridges.

Eterna-Lube #1000

Temperature: -40°C to + 1093°C

Delivered in drum: 181 or 54 kg Pail: 18 or 4,5 kg Cartridges: 430 gram

4,5 kg pail are used directly with the pneumatisk pumpe Active-8 and the cartridges are to be used with the manual hand pump Super gun screw-primed pump. Cartridges are delivered in boxes of 12 cartridges.

Mohave Body Fill

Mohave body filler is a synthetic lubricants for body filling of wellhead gate valve. It is a corrosion inhibiting grease that eases valve operation by lubricating the internal component and moving parts. It is also designed to remain pliable in all kind of operating conditions and reduces breakout torque on tight and hard-to-turn valves. Mohave body fill can be injected into valve stems and seat sealant systems for additional protection and is recommended for use in methane, ethane, propane, butane, alkalis, dilute acids and salt water processing

Pressure up to 690 bar (10 000 PSI)

Temperatur område: – 18°C til + 149°C

Delivered in drum: 181 or 54 kg Pail: 18 or 4,5 kg Cartridges: 430 gram

4,5 kg pail are used directly with the pneumatisk pumpe Active-8 and the cartridges are to be used with the manual hand pump Super gun screw-primed pump. Cartridges are delivered in boxes of 12 cartridges.

Sealing component

Total-Lube #911

Pressure up to 690 bar (10 000 PSI)

Temperature: – 29°C to + 232°C

Delivered in drum: 181 or 54 kg Pail: 18 or 4,5 kg Cartridges: 430 gram

4,5 kg pail are used directly with the pneumatisk pumpe Active-8 and the cartridges are to be used with the manual hand pump Super gun screw-primed pump. Cartridges are delivered in boxes of 12 cartridges.

Ball valve Sealant #5050

Sealweld Ball Valve Sealant #5050 provides an insoluble film of lubricant to protect seal faces and reduce torque requirements. Specially processed particles of PTFE will seal scratches to sealing surfaces up to 0.030″. Will not harden or plug off conventional giant buttonhead sealant injection fittings. #5050 is ideal for use in natural gas, water, oil, and related by-products. Use in ball, gate and plug valves, orifice fittings, valve stems and seat seals with minor to severe leakage problems. Use at refineries, wellheads, pump or compressor stations and in gas distribution systems. Suitable for crude oil, sour gas, CO2, water/ brine solutions, and refined petroleum product pipelines.

For best results, first inject Sealweld Valve Cleaner Plus, then leave in the valve for 30 – 40 minutes (up to 8 hours for problem valves). Purge the system with Sealweld Total-Lube #911. Inject Ball Valve Sealant #5050 if Total-Lube #911 fails to hold a reliable seal. #5050 is also available in heavier grades for severely leaking valves and emergency valve sealing conditions.

This product is available in a wide range of extra heavy grades with increasing amounts of PTFE. Designed for use by qualified technicians ONLY. Contact Sealweld for consultation prior to application of these products.

Pressure up to 690 bar (10 000 PSI)

Temperature: – 29°C to + 232°C

Delivered in drum: 181 or 54 kg Pail: 18 or 4,5 kg Cartridges: 430 gram

4,5 kg pail are used directly with the pneumatisk pumpe Active-8 and the cartridges are to be used with the manual hand pump Super gun screw-primed pump. Cartridges are delivered in boxes of 12 cartridges.

Winter-Lube #7030

Sealweld Winter-Lube #7030 is a synthetic-based lubricant designed specifically for use in sub-zero winter climates where conventional sealants become stiff and too hard to pump. Unique additives provide excellent low-temperature pumping ability and lower operating torque in severe operating conditions. Sealweld Winter-Lube #7030 can be used year-round in all types of service. Formulated to remain insoluble in water, oil, all types of hydrocarbon services including natural gas, condensate, related by-products, crude oil and refined petroleum products. Use in ball, gate and plug valves. Recommended for use on: above ground valves such as blow-down valves, pig launching and receiving valves and in refineries, wellheads, pump or compressor stations and in gas distribution systems. Suitable for use in Sour Service.

Pressure up to 690 bar (10 000 PSI)

Temperature: – 40°C to + 205°C

Delivered in drum: 181 or 54 kg Pail: 18 or 4,5 kg Cartridges: 430 gram

4,5 kg pail are used directly with the pneumatisk pumpe Active-8 and the cartridges are to be used with the manual hand pump Super gun screw-primed pump. Cartridges are delivered in boxes of 12 cartridges.

Low-Temperature Lubricant D-1014

Sealweld Low-Temperature Lubricant D-1014 is a proprietary blend of synthetic materials formulated with low-temperature additives. D-1014 significantly reduces torque requirements, counters the extreme drying effects produced by liquefied petroleum gases and lubricates long after other types of lubricants have been washed out. Sealweld Low-Temperature Lubricant D-1014 makes an excellent gear box lubricant. Recommended for use in LPG/ NGL services including propane, butane, ethane, ethylene and related by-products. Ideal for use in ball, gate, plug, wellhead valves and other valves designed to be left offline in extreme climate conditions and must be available for actuation as in the case of pig traps and launchers.

Pressure up to 690 bar (10 000 PSI)

Temperature: – 54°C to + 204°C

Delivered in drum: 181 or 54 kg Pail: 18 or 4,5 kg Cartridges: 430 gram

4,5 kg pail are used directly with the pneumatisk pumpe Active-8 and the cartridges are to be used with the manual hand pump Super gun screw-primed pump. Cartridges are delivered in boxes of 12 cartridges.

Pumps and pump equipment

To execute valve maintenance you will need a pump and some pump equipment. The pump can be either manual or pneumatic.

Active-8 pump

The Activ-8 pump are a pneumatic pump used on the 4,5 kg pail. The pump can run on a compressor, bottled air or in an emergency by natural gas.

The Activ-8 pump are a pneumatic pump used on the 4,5 kg pail. The pump can run on a compressor, bottled air or in an emergency by natural gas.

The pump is generating 10 000 PSI (690 bar), controlling the pumped volume to avoid over filling.

The pump can give 1/2 kg in 70 second and are ideal for filling large volumes or when maintaining a great number of valves.

The pump is delivered with a 3 meter hose, swivels and couplers, 15 000 PSI gauge is standard. Extra long hoses can be ordered. The pump are delivered with an 8 minute instruction DVD.

Supergun Screw-Primed Pump

The Sealweld SuperGun® Pump has an extra long lever handle that makes high-pressure injection easy. It is lightweight and very portable. The screw-primed design indicates how much product remains in the barrel and the high-pressure check valve system prevents dangerous “kicks”.

The Sealweld SuperGun® Pump has an extra long lever handle that makes high-pressure injection easy. It is lightweight and very portable. The screw-primed design indicates how much product remains in the barrel and the high-pressure check valve system prevents dangerous “kicks”.

The SuperGun® Pump has been designed to withstand the rigors of field use and every pump is tested prior to shipment. Durability, easy to carry and faster pumping make it the valve technicians favorite hand-held, high-pressure sealant injection pump for topping-up procedures when only small quantities of lubricant is required.

The pump is generating up to 15 000 PSI (1030 bar) and 25 strokes will give 1 ounce (0,3 dl), 85 strokes will give 1 dl of lubricant. Due to the high pressure one must be careful not to damage the check valve inside the fitting. It is essential to take the time needed when doing valve maintenance.

EZ-Loader

The Sealweld EZ-Loader was designed to make loading cartridges quick and easy. Just pull back the T-handle, insert a cartridge, screw on the adapter and transfer the lubricant/ sealant into the high-pressure pump barrel. No waste, no mess and easy to store.

The Sealweld EZ-Loader was designed to make loading cartridges quick and easy. Just pull back the T-handle, insert a cartridge, screw on the adapter and transfer the lubricant/ sealant into the high-pressure pump barrel. No waste, no mess and easy to store.

The use of cartridge type lubricant/sealants has been found to greatly reduce the risk of product contamination and trapped air in any pump.

Transportation case

A transportation case are useful to have fore safe storage and transportation of the pump. It is easy to damage the gauge or swivel if the pump is not proper secured in storage. The transportation of the pump are safer and easier with the inside a case.

A transportation case are useful to have fore safe storage and transportation of the pump. It is easy to damage the gauge or swivel if the pump is not proper secured in storage. The transportation of the pump are safer and easier with the inside a case.

Swivel

Not many spare parts are needed for the pumps, but one or two extra swivels may be needed. The swivel is a weak part of the pump, it is easy breakable if a pump by accident are dropped to the floor. The pump can be used without the swivel but is some more problematic to handle without the flexibility given by the swivel.

Not many spare parts are needed for the pumps, but one or two extra swivels may be needed. The swivel is a weak part of the pump, it is easy breakable if a pump by accident are dropped to the floor. The pump can be used without the swivel but is some more problematic to handle without the flexibility given by the swivel.

Leak-Lock

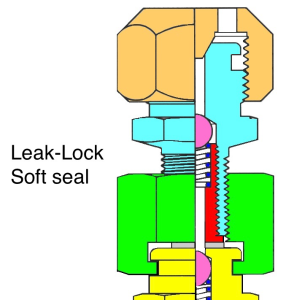

Soft sealed

Convert leaking or damaged fittings into safe fittings without shut-down or loss of production. Leak-Lock is not a permanent repair device but should be used until a scheduled turn-around or when the pipeline is depressurised and the leaking fitting can be replaced safely. Also for use on damaged button head fittings.

Convert leaking or damaged fittings into safe fittings without shut-down or loss of production. Leak-Lock is not a permanent repair device but should be used until a scheduled turn-around or when the pipeline is depressurised and the leaking fitting can be replaced safely. Also for use on damaged button head fittings.

Can be used in applications where a second independent check valve is required to comply with safety codes or company policy. Can be left on permanently or until the pipeline is depressurized and the existing fitting can be replaced safely.This emergency sealing device fits on a leaking or damaged giant buttonhead fitting. Uses a replaceable gasket seal. Ideal for old or leaking fittings or when you need to go from giant buttonhead to threaded coupler.

Seal type: Gasket

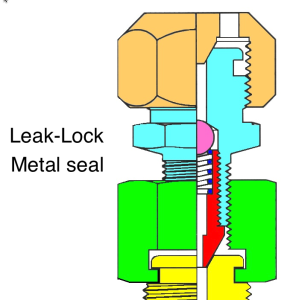

Metal sealed

The Flow Wolf Leak-Lock #1 Metal-Seated Adapter is designed for use on capped fittings ONLY. It provides and additional check valve so you can continue to service the valve in-line, under pressure.

The Flow Wolf Leak-Lock #1 Metal-Seated Adapter is designed for use on capped fittings ONLY. It provides and additional check valve so you can continue to service the valve in-line, under pressure.

Seal type: Metal-to-Metal

The new Flow Wolf style Leak-Lock Adapter has all the features of a regular Leak-Lock plus an additional metal-to-metal seal (with cap). Will accept liquids and pass the heaviest sealants without plugging off.