The how (and why) of maintenance part 7

The use of sealing component as a barrier

As one can understand, the lubrication fittings to the stem are an important part when it comes to prolonging the life span of a valve. As discussed in previous articles it is possible to save millions by millions when prolonging the life of a leaky valve. When the argument comes that the use of sealing component as a sealing agent are a temporary seal, I normally answer that it is a temporary/permanent solution. If the stem seal seals and don’t leak it´s fine, just leave it, and if the day comes that the stem starts to leak again. Well, inject some more. If this works the valve is fine.

When it comes to the internal leak past the seats, it´s another ball game, because the sealing component witch makes the seal will disappear the next time the valve is operated.

We all know that there are different leak rates when it comes to API 6D ball, plug or gate valves. Soft-seated valves should as new be bobble tight but metal-to-metal sealed valves normally do have a leak rate in accordance with their seal class. This may cause some confusion at the plant the day they are shutting down part of the plant for maintenance or replacement of equipment. The experiences from both old and new plants are the many of the valves do leak; it may be just a relatively small leak or a massive flow through the valve.

Figure 37

Figure 37

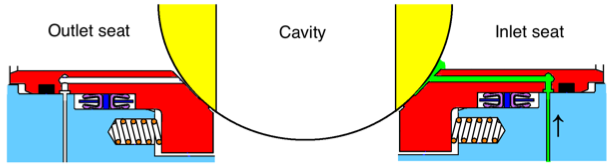

There are two possible leak points on the seat to a trunnion mounted ball valve:

- On the radial seal on the outside of the seat, illustrated in figure 37 by an O-ring suffered from ED

Figure 38

Figure 38

- The axial seal towards the ball, which can be soft or metal sealed. This may be damage to the soft seal as illustrated in figure 38 where the soft seal was sucked out of the seat by opening with DP. Or it may be scratches on the seal surface on the seat or the ball as illustrated in figure 39.

Figure 39

Figure 39

Sediments trapped in between the seat and ball as illustrated in figure 40 could also cause the internal leak. As previously discussed there may also be sediments on the seal surface of the ball, which will prevent the seat in getting a good seal against the ball.

Figure 40

Figure 40

To be able to obtain a seal between the seat and the ball there are several conditions that must be present.

The seal surface must be in a good condition on both the ball/gate and the seat. The radial seal between the seat and the seat pocket must be in a good condition too. And the seat friction towards the seat pocket must be less than the force of the springs on the back of the seat. If the springs are unable to move the seat in contact with the ball the valve will leak no matter the condition of the seals.

In this serious of articles, I have tried to give several reasons why there should be installed lubrication fittings on a trunnion ball or parallel gate valve. I do think that there are more reasons in favour of installation of lubrication fittings than there are reasons for not installing them.

Let’s go to a situation involving one 12” metal-to-metal sealed trunnion mounted class 1500 double piston ESD valve. The valve should be used as a barrier in conjunction with replacement work on the downstream side of the valve. When depressurising the downstream side of the valve the valve sealed, but when trying to reduce the cavity pressure the upstream seat did have a leak into the cavity. The valve was equipped with two lubrication fittings to each seat; which enables cleaning of the valve. Valve cleaning was carried out and the leak rate was reduced, but the leak into the cavity was still too much. Now question about the ESD reliability and the possible barrier with regards to the planned downstream work was raised.

Figure 41

Figure 41

Is the valve still reliable as an ESD valve when upstream seal is leaking?

My answer was yes, it is. The reason; when a ESD valve closes and/if the pressure on the downstream side are evacuated, the valve will seal as the downstream seal always will be the main seal when a double piston valve is closed. It does not matter if it is the upstream seat on a self-relief valve that seal or it is the downstream seat on a double piston valve that seal. In an ESD situation both valves will seal with only one seat.

When it came to establishing double barrier on the valve with a leaky inlet seat (which can be achieved if the valve is equipped with the sufficient numbers of lubrication fitting to the seats) it could be achieved by using sealing component. After cleaning the valve, you can inject sealing component to the inlet seat as illustrated in figure 41. When injecting sealing component reduce the cavity pressure to 50% of the inlet pressure and try to seal of the inlet leak with sealing component. If the inlet seat seals and having 10-20 bar in the cavity the valve do have a double barrier and I don’t see any reasons why the valve should be replaced.

You should newer use a component that can dry out when inside the valve. If drying out the injection of sealing component can lead to more trouble and possibly replacement of the valve.

With the right use of valve cleaner and sealing component you may extend the lifetime of the valves many times over. But remember you cannot seal of major damages done by erosion or cavitation. Sealing component can only seal of scratches and damages up to 0.5 – 0.7 of a millimetre.

To be continued

Do you want to download this article as a PDF?

Click here to download